Inside Kangsheng: Our Advanced Stone Fabrication Process

For distributors and developers, choosing a partner goes beyond the product itself. What makes a reliable stone manufacturer? The answer lies in their process, technology, and commitment to quality. This article takes you behind the scenes of our advanced stone fabrication process. It shows how we transform raw materials into exceptional products. To see our full capabilities, you can explore our company profile.

From Raw Material to Perfect Slab: The Foundation of Quality

What is the stone production process? It all starts with the finest materials and a meticulous formation process. This foundational stage is critical for the final quality of every slab.

Sourcing High-Purity Quartz and Resins

Our production process begins with sourcing high-purity quartz crystals. We select only the best raw materials. This ensures superior hardness and clarity in the final product. We blend these materials with high-performance resins and pigments to create the desired look and feel.

The Vibrocompression and Curing Process

The blended material is then subjected to vibrocompression under vacuum. This step is vital. It removes air pockets and creates an ultra-dense, non-porous slab. After this, the slabs are cured in a controlled environment. This process solidifies the material and ensures maximum strength.

Ensuring Slab Density and Consistency

Throughout this initial stage, we monitor every parameter. This ensures each quartz slab has uniform density and consistency. This commitment to foundational quality is what sets a premier quartz slab manufacturer apart.

Precision Cutting: The Role of Advanced Machinery

How is stone fabricated with such accuracy? The answer lies in our investment in advanced facilities. Our cutting-edge machinery allows for unparalleled precision.

Infrared Bridge Saws for Accurate Sizing

We utilize infrared bridge saws for cutting slabs to standard or custom sizes. These machines use a laser guide to ensure every cut is perfectly straight and accurate. This technology is essential for efficient and precise precision cutting.

CNC Technology for Complex and Custom Shapes

For more complex designs, we employ computer numerical control (CNC) machines. This technology allows us to execute intricate curves, angles, and custom shapes with flawless accuracy. It is the core of our custom fabrication services.

Minimizing Waste and Maximizing Efficiency

Our advanced machinery is not just about precision; it's also about efficiency. We use sophisticated software to optimize cutting layouts. This minimizes material waste, which helps control costs for our clients.

Achieving the Perfect Finish: Our Automated Polishing and Honing Lines

The surface finish of a stone slab defines its final look and feel. Our automated lines ensure a perfect finish every time.

Multi-Head Polishing Machines for a Flawless Gloss

Our automated, multi-head polishing lines create a deep, lustrous, and highly reflective gloss. The machines use a sequence of abrasive heads to gradually smooth the surface. This results in a durable and beautiful polished finish.

Creating Consistent Honed and Matte Surfaces

Beyond polishing, we can create sophisticated honed and matte finishes. This process requires precise control to achieve a uniform, low-sheen surface. Our automated lines guarantee that this modern look is consistent across every slab.

The Importance of Calibration for Uniform Thickness

Calibration is a critical step in our production process. We ensure every slab has a uniform thickness from edge to edge. This consistency is vital for easy installation and a seamless final appearance.

Edge Profiling and Custom Fabrication: Tailored for Your Project

As a leading stone manufacturer, we pride ourselves on our custom capabilities. We can tailor products to meet the specific needs of any project.

A Variety of Standard Edge Profiles

We offer a wide range of standard edge profiling options. These include eased, beveled, and bullnose edges. These finishes add a professional touch to any countertop or surface.

Capabilities for Custom Edge Designs

For unique projects, we offer fully custom edge designs. Our custom fabrication team can work with your specifications to create a one-of-a-kind look. Contact our team to discuss your custom needs.

Cutouts for Sinks and Cooktops

Our factory can precisely cut openings for sinks, cooktops, and other fixtures. This factory-finished service saves time and labor on the job site. It also ensures a perfect fit.

Rigorous Quality Control: The Final Step Before Shipping

How do you ensure quality in stone slabs? Our multi-stage quality control process is our guarantee. No product leaves our factory without passing our stringent inspections.

Visual Inspection for Color and Pattern Matching

Our QC team visually inspects every slab. They check for color and pattern consistency against the master sample. This ensures that your entire order matches perfectly.

Digital Measurement for Dimensional Accuracy

We use digital tools to verify all dimensions. This includes length, width, thickness, and the accuracy of any cutouts. This guarantees that the product you receive meets your exact specifications.

Export-Grade Crating and Packaging

Finally, we package our slabs in sturdy, custom-built wooden crates. This export-grade packaging protects the stone during international shipping. It ensures your order arrives safely at its destination.

The Kangsheng Difference: Technology, Precision, and Partnership

The journey from raw material to finished product is a complex one. It requires a blend of quality materials, advanced technology, and skilled craftsmanship. At Kangsheng, our stone fabrication process is built on precision and a commitment to excellence. We are not just a supplier; we are a manufacturing partner dedicated to your project's success.

See our capabilities for yourself. Contact us to schedule a virtual factory tour or to discuss the technical requirements for your next project.

Frequently Asked Questions about Our Stone Fabrication Capabilities

What is your factory's monthly production capacity?

Our factory is equipped with advanced facilities to handle large-scale orders. Our monthly production capacity is approximately 300,000 square meters, allowing us to serve large commercial and residential projects reliably.

How do you ensure color consistency across different production batches?

We maintain strict quality control over our raw materials and production parameters. Master samples are used to ensure color and pattern consistency from one batch to the next, making us a reliable partner for phased projects.

Can you handle large, complex custom orders for commercial projects?

Yes. Our expertise in custom fabrication and our advanced CNC machinery allow us to handle large, complex, and high-precision orders for commercial clients worldwide.

What is the typical lead time from order to shipping?

Our typical lead time is between 7-10 days for production, depending on the order size and complexity. We are committed to fast and efficient delivery. For a specific timeline for your project, please contact our sales team.

Optimize Your Project with Cut-to-Size Stone Slabs

Optimize Your Project with Cut-to-Size Stone Slabs

Inside Kangsheng: Our Advanced Stone Fabrication Process

Inside Kangsheng: Our Advanced Stone Fabrication Process

What is Nano Crystallized Glass Stone? A Deep Dive

What is Nano Crystallized Glass Stone? A Deep Dive

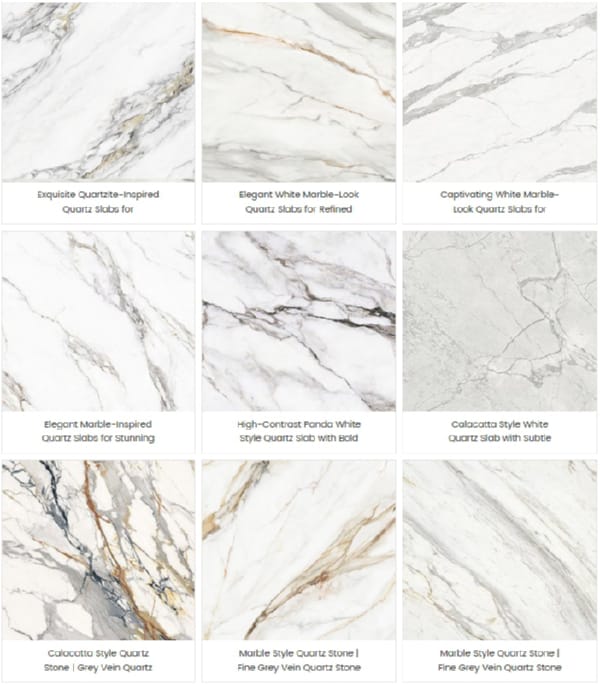

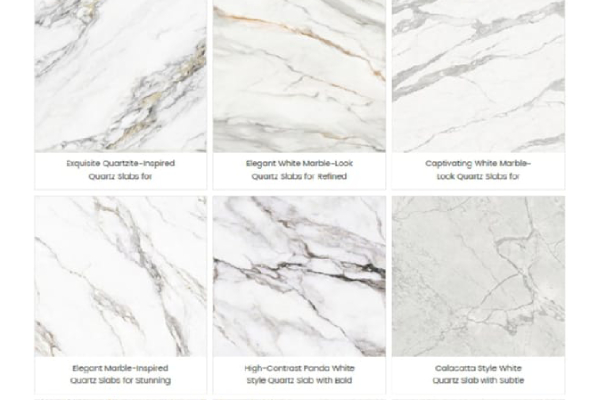

Get the Marble Look Without the Maintenance

Get the Marble Look Without the Maintenance

The Ultimate Guide to Engineered Quartz Countertops

The Ultimate Guide to Engineered Quartz Countertops

Quartz vs. Granite: A Comparison for Developers

Quartz vs. Granite: A Comparison for Developers