The Ultimate Guide to Engineered Quartz Countertops

When selecting the perfect surface for modern interiors, designers and developers face a crucial choice. They need a material that is both beautiful and resilient. What is engineered quartz and why is it consistently the top choice? This guide explores why engineered quartz countertops are the superior solution for today's design challenges. Discover the benefits of this remarkable material and explore our engineered stone collection.

What Exactly Is Engineered Quartz? The Science Behind the Stone

Many people wonder how quartz is made. Unlike natural stone slabs mined directly from the earth, engineered quartz is a composite material. It offers the best of both worlds: nature's beauty and human ingenuity.

Composition: A Blend of Nature and Technology

Engineered quartz primarily consists of natural quartz crystals. In fact, it contains up to 93% crushed quartz. Manufacturers blend these crystals with high-quality polymer resins and pigments. This precise composition creates a remarkably durable and non-porous surface. The result is a material that overcomes the limitations of natural stone.

The Manufacturing Process: How Slabs Are Made

The creation of an engineered quartz slab is a highly controlled process. First, the raw materials are mixed and blended. Then, the mixture is poured into a mold to form a slab. It undergoes a process of vibrocompression under vacuum. This step removes air and compacts the material densely. Finally, the slab is cured, polished, and finished to exact specifications. This meticulous stone fabrication ensures every slab has consistent quality and appearance.

The Unbeatable Advantages of Quartz Countertops for Any Project

Why choose quartz countertops? The benefits are clear, especially for high-traffic residential and commercial projects. This engineered stone delivers superior performance across the board.

Unmatched Durability: Scratch and Chip Resistance

Is engineered quartz durable? Absolutely. Quartz is one of the hardest minerals on earth. This inherent strength makes engineered quartz highly resistant to scratches, chips, and impacts. It can easily withstand the daily wear and tear of a busy kitchen or commercial space. This makes it one of the most durable countertops available.

Non-Porous Surface: A Hygienic, Stain-Resistant Choice

The manufacturing process creates a non-porous surface. This means liquids and bacteria cannot penetrate the material. This hygienic surface is a key benefit, making it incredibly stain-resistant. Spills like wine, coffee, or oil can be wiped away easily without leaving a trace. This quality makes it a superior choice among various countertop materials.

Low Maintenance: No Sealing Required

Is quartz easy to maintain? Yes, very. Unlike natural stone like granite or marble, engineered quartz never needs sealing. Its non-porous nature means it is already protected from stains and moisture. A simple cleaning with soap and water is all that is required. This low maintenance quality saves time and money over the long term.

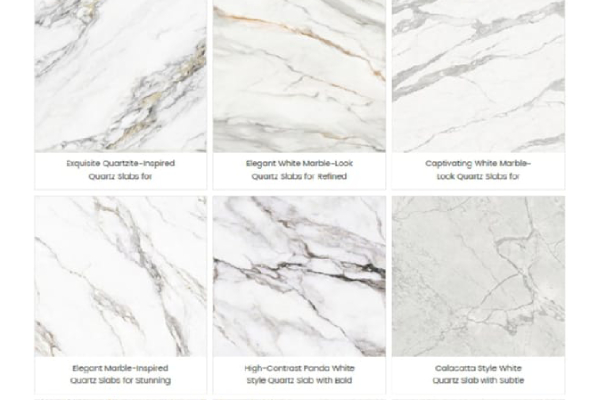

Consistency in Color and Pattern

Because it is a manufactured product, every quartz slab offers consistency. The color and pattern are uniform throughout the slab. This is a significant advantage for large projects. It ensures a seamless and predictable look across multiple countertops or wall panels. You can discover consistent and beautiful quartz slabs for your project needs.

A World of Design: Exploring the Aesthetic Versatility of Engineered Quartz

One of the greatest benefits of engineered stone is its design versatility. The manufacturing process allows for an almost limitless range of styles, from minimalist to luxurious.

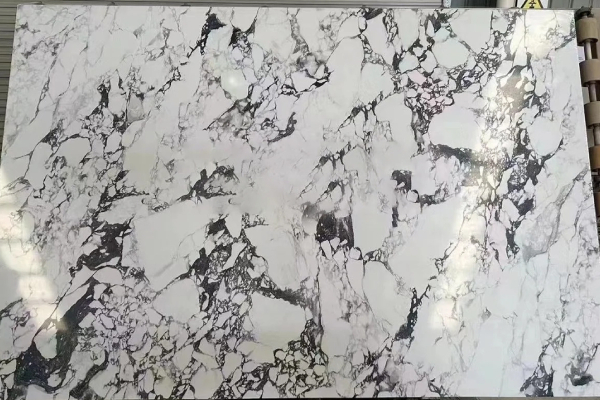

Endless Color Possibilities: From Pure Whites to Bold Blacks

Engineered quartz is available in a vast spectrum of colors. You can find brilliant whites, deep blacks, and every shade in between. This allows designers to perfectly match any color palette. The pigments are mixed in for a rich, consistent hue. This level of color control is impossible with most natural stones.

Mimicking Nature: The Beauty of Marble-Look Quartz

Can quartz look like marble? Yes, and the results are stunning. Advanced technology allows manufacturers to create intricate veining and patterns. This marble look quartz captures the elegance of natural marble. However, it does so without the associated drawbacks of porosity and fragility. You can achieve a classic, high-end look with superior performance.

Choosing Your Finish: Polished, Honed, or Matte

The aesthetic appeal of a countertop also depends on its finish. Engineered quartz offers various options to suit different design styles. A polished finish provides a glossy, reflective look. A honed or matte finish offers a soft, low-sheen appearance. This choice in stone textures allows for complete design customization.

Beyond the Kitchen: Where to Use Engineered Quartz Slabs

While perfect for kitchen countertops, the use of engineered quartz extends far beyond. Its durability and beauty make it suitable for numerous applications.

Luxurious Bathroom Vanities

The non-porous and hygienic surface of quartz is ideal for bathrooms. It resists moisture, mold, and mildew. This makes it a perfect material for vanities and shower surrounds.

Seamless Wall Cladding and Backsplashes

Large quartz slabs can be used for dramatic backsplashes or feature walls. The consistency of the material creates a clean, seamless look. This is especially effective with large-format slabs, minimizing grout lines.

High-Impact Commercial Spaces & Reception Desks

Engineered quartz is an excellent choice for commercial applications. It can handle the high traffic of reception desks, bar tops, and retail counters. Its durability ensures it will look great for years to come. For your next commercial project, consider our range of durable engineered stone.

Engineered Quartz vs. Other Countertop Materials: A Quick Comparison

How does engineered quartz stack up against other popular materials? Here is a brief comparison.

Quartz vs. Granite

Granite is a porous natural stone that requires regular sealing. Quartz is non-porous and needs no sealing. While both are durable, quartz offers better stain resistance and color consistency.

Quartz vs. Marble

Marble is known for its beauty but is soft and porous. It scratches and stains easily. Quartz offers the same elegant look but with far superior durability and stain resistance.

A Summary Table for Easy Decision-Making

| Feature | Engineered Quartz | Granite | Marble |

|---|---|---|---|

| Durability | Excellent | Very Good | Fair |

| Stain Resistance | Excellent | Good (if sealed) | Poor |

| Maintenance | Low (no sealing) | Medium (sealing) | High (sealing) |

| Consistency | Excellent | Varies | Varies |

| Design Options | Virtually Unlimited | Limited by Nature | Limited by Nature |

Why Engineered Quartz is a Smart Investment for Your Next Project

In summary, engineered quartz countertops offer a powerful combination of style, strength, and practicality. From its unmatched durability to its endless design possibilities, it stands out as the premier choice among modern countertop materials. It is a smart investment that delivers long-lasting value and beauty for any residential or commercial project. Contact Kangsheng Stone specialists to find the perfect quartz solution for you.

Frequently Asked Questions (FAQ) about Engineered Quartz

Is engineered quartz real stone?

Engineered quartz is a composite material made of about 93% natural quartz crystals, bonded with resins. While not a solid slab of natural stone, its primary ingredient is real stone, giving it incredible strength.

Can you put hot pans on engineered quartz?

It is always recommended to use trivets or hot pads. While quartz is heat-resistant, sudden and extreme temperature changes (thermal shock) can potentially damage the resin binders.

How much do quartz countertops cost compared to granite?

The cost of quartz and granite is often comparable. Pricing depends on the quality, color, and complexity of the design. However, quartz's low maintenance can result in lower lifetime costs. To get a precise quote for your project, you can request a consultation from our experts.

Our Stone Quality Control: A Commitment to Excellence

Our Stone Quality Control: A Commitment to Excellence

Decoding Stone Finishes: Polished vs. Honed vs. Matte

Decoding Stone Finishes: Polished vs. Honed vs. Matte

Beyond the Countertop: Innovative Stone Slab Uses

Beyond the Countertop: Innovative Stone Slab Uses

Optimize Your Project with Cut-to-Size Stone Slabs

Optimize Your Project with Cut-to-Size Stone Slabs

Inside Kangsheng: Our Advanced Stone Fabrication Process

Inside Kangsheng: Our Advanced Stone Fabrication Process

What is Nano Crystallized Glass Stone? A Deep Dive

What is Nano Crystallized Glass Stone? A Deep Dive

Get the Marble Look Without the Maintenance

Get the Marble Look Without the Maintenance

Quartz vs. Granite: A Comparison for Developers

Quartz vs. Granite: A Comparison for Developers

The Ultimate Guide to Engineered Quartz Countertops

The Ultimate Guide to Engineered Quartz Countertops