Quartz vs. Granite: A Comparison for Developers

Making the right choice for a large-scale project is critical. When it comes to countertops, the classic quartz vs. granite debate is a major consideration for developers and wholesalers. Which is better for a large project, quartz or granite? This in-depth comparison will analyze both materials from a commercial perspective. We will help you make a strategic decision for your next development. For a detailed look at our offerings, you can explore our stone slab collections.

Durability in High-Traffic Areas: A Performance Test

For any commercial space or multi-family housing project, durability is non-negotiable. The chosen material must withstand heavy use. Is quartz more durable than granite? Let's examine the facts.

Hardness and Scratch Resistance

Engineered quartz is one of the hardest materials available for countertops. It scores around 7 on the Mohs hardness scale. Granite typically ranges from 6 to 7. This means quartz offers slightly superior scratch resistance. This is a crucial factor for durable countertops in high-traffic environments.

Chip and Impact Resistance in Commercial Settings

The resin binders in engineered quartz give it a degree of flexibility that natural stone lacks. This makes it more resistant to chipping and impact. For busy commercial countertops, this added resilience can mean fewer repairs and a longer lifespan. This is a key part of any serious stone slab comparison.

Heat Resistance Comparison

Both materials handle heat well. However, granite has a slight edge in resisting very high temperatures. It is recommended to always use trivets for hot pans on both surfaces. For most commercial applications, the heat resistance of quartz is more than sufficient.

Maintenance and Lifetime Cost: A Wholesaler's Perspective

Initial cost is only part of the equation. Developers and property managers must consider long-term maintenance. Does granite need more maintenance than quartz? The answer significantly impacts lifetime cost.

The Sealing Requirement of Granite Countertops

Granite is a porous natural stone. It must be sealed upon installation and resealed periodically. This prevents it from absorbing liquids and staining. This regular maintenance adds to the long-term operational cost of a property.

Quartz: A Non-Porous, Zero-Sealing Solution

In the quartz vs. granite debate, this is a major advantage for quartz. It is non-porous and never requires sealing. This eliminates ongoing maintenance costs and effort. It also provides a more hygienic surface, resistant to bacteria and mold. This feature makes it an ideal choice for high-quality kitchen countertops.

Calculating Long-Term Ownership Costs

When you factor in the cost of sealing and potential stain repairs, the lifetime cost of granite can exceed that of quartz. For large-scale projects, the savings from choosing low-maintenance quartz can be substantial.

Aesthetic Consistency vs. Natural Uniqueness: A Design Standoff

The visual appeal of a countertop is paramount. Quartz and granite offer two distinct aesthetic approaches.

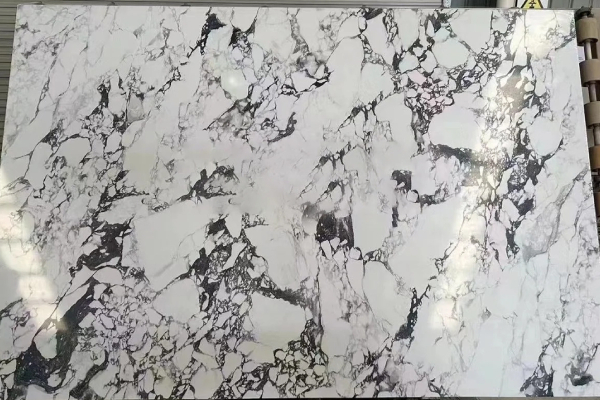

The Appeal of Granite's One-of-a-Kind Patterns

Each slab of granite is unique. Its patterns and colors are formed by nature. This can be a selling point for bespoke, high-end projects where every piece is different. However, this uniqueness can be a challenge for larger developments.

The Advantage of Quartz's Uniformity for Large Projects

Engineered quartz provides exceptional consistency. The color and pattern are uniform from slab to slab. For a project with hundreds of units, this ensures a cohesive and predictable design aesthetic. This project scalability is a key benefit for developers.

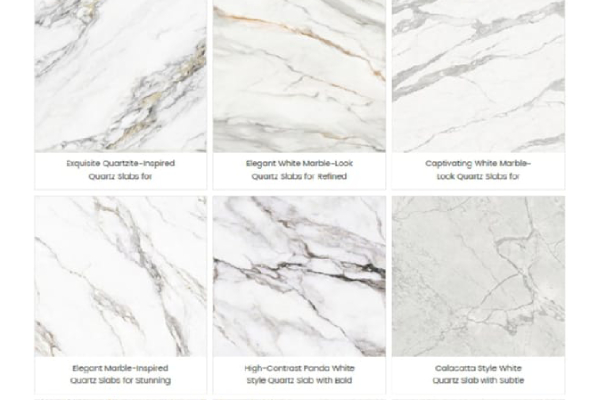

Color and Pattern Availability

Granite's color palette is limited by what nature provides. Quartz, on the other hand, offers a nearly limitless range of colors and patterns. This includes solid colors and designs that mimic other stones, like marble. Our quartz slab selection showcases this versatility.

Supply Chain and Project Scalability: A Developer's Concern

Is quartz or granite better for commercial use from a supply standpoint? The reliability of the supply chain is crucial for keeping a project on schedule.

Sourcing Natural Granite Slabs: Potential Challenges

Sourcing large quantities of matching granite countertops can be difficult. A quarry may run out of a specific stone, or color variations between lots can be significant. This creates risk and potential delays for large projects.

Engineered Quartz: Reliable Supply and Consistent Quality

As a manufactured product, engineered quartz offers a reliable and predictable supply. We can produce large quantities of a specific design with minimal variation. This ensures that materials for all phases of a project will match perfectly.

Managing Color Lots for Phased Projects

For phased developments, managing color lots is essential. With engineered quartz, developers can be confident that the slabs ordered months apart will maintain their aesthetic integrity. This level of quality control is a major advantage for any large-scale stone project.

The Bottom Line: An Honest Look at a Quartz vs. Granite Slab Comparison

Let's bring it all together. Is quartz cheaper in bulk than granite? The answer depends on several factors.

Initial Slab Cost Analysis

The initial cost per square foot for entry-level quartz and granite can be similar. However, high-end and exotic granites can be much more expensive. Conversely, complex quartz designs also command a premium.

Factoring in Fabrication and Installation

Fabrication costs are generally comparable. However, the consistency of quartz can sometimes lead to less waste during cutting. This can result in modest savings on larger projects.

Summary Chart: Quartz vs. Granite

| Factor | Quartz | Granite |

|---|---|---|

| Durability | Higher | High |

| Maintenance | None | Periodic Sealing |

| Consistency | Excellent | Varies |

| Supply Chain | Reliable | Variable |

| Lifetime Cost | Lower | Higher |

Why Quartz is the Strategic Choice for Commercial Countertops

After a thorough stone slab comparison, the verdict is clear. While granite countertops offer natural beauty, quartz presents a more compelling package for developers and wholesalers. Its superior durability, zero maintenance, design consistency, and reliable supply chain make it the strategic choice for commercial countertops and large-scale residential projects. It is an investment in quality, efficiency, and long-term value.

Planning a large-scale project? Contact our B2B specialists today to discuss your requirements and get a competitive quote for our premium quartz slabs.

Frequently Asked Questions for Developers and Wholesalers

For a rental apartment complex, is quartz or granite a better investment?

Quartz is generally a better investment for rental properties. Its superior durability and low maintenance reduce turnover costs and operational burdens. The stain resistance also ensures the countertops look new for longer.

Can I get volume discounts on quartz slabs for a large project?

Yes. As a manufacturer, we offer competitive pricing for bulk orders. We work directly with developers and distributors to provide cost-effective solutions. Inquire about our wholesale pricing.

How does the weight of quartz compare to granite for installation purposes?

Quartz and granite have similar densities and weights. Installation requirements are comparable for both materials. Our team can provide detailed technical specifications for your project planning.

Which material offers more modern design options?

Quartz offers far more modern design options. It is available in a wide array of solid colors, subtle patterns, and finishes like matte and honed. This versatility makes it easier to match contemporary design aesthetics.

Our Stone Quality Control: A Commitment to Excellence

Our Stone Quality Control: A Commitment to Excellence

Decoding Stone Finishes: Polished vs. Honed vs. Matte

Decoding Stone Finishes: Polished vs. Honed vs. Matte

Beyond the Countertop: Innovative Stone Slab Uses

Beyond the Countertop: Innovative Stone Slab Uses

Optimize Your Project with Cut-to-Size Stone Slabs

Optimize Your Project with Cut-to-Size Stone Slabs

Inside Kangsheng: Our Advanced Stone Fabrication Process

Inside Kangsheng: Our Advanced Stone Fabrication Process

What is Nano Crystallized Glass Stone? A Deep Dive

What is Nano Crystallized Glass Stone? A Deep Dive

Get the Marble Look Without the Maintenance

Get the Marble Look Without the Maintenance

Quartz vs. Granite: A Comparison for Developers

Quartz vs. Granite: A Comparison for Developers

The Ultimate Guide to Engineered Quartz Countertops

The Ultimate Guide to Engineered Quartz Countertops