Our Stone Quality Control: A Commitment to Excellence

In the global stone market, consistency is king. How to find a trustworthy stone supplier? The answer lies in their commitment to quality. A robust stone quality control system is the backbone of any reliable manufacturer. At Kangsheng Stone, this is not just a department; it's our core philosophy. This article details our comprehensive approach to quality. We want to show you why we are a trustworthy supplier. Learn more about our commitment to quality.

Stage 1: Rigorous Raw Material Inspection

How do you ensure stone quality from the very beginning? It all starts with the raw materials. The final product can only be as good as its components.

Purity and Particle Size Analysis

Before any material enters our production line, it undergoes strict inspection. We analyze the purity of the quartz sand and the particle size distribution. This ensures the final slab will have superior strength and a uniform appearance.

Color Consistency Checks for Pigments

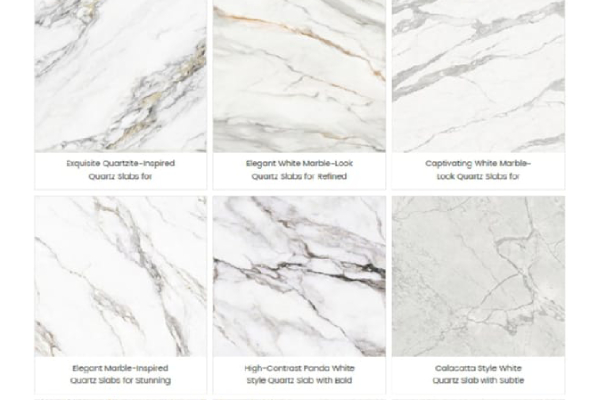

We source high-quality pigments to create our diverse color palette. Each batch of pigment is checked for color consistency. This guarantees that a slab produced today will match one produced months from now.

Resin Quality and Performance Testing

The resin is a critical component in a quartz slab. We test its performance for bonding strength, clarity, and UV resistance. This ensures the long-term durability and color stability of our products.

Stage 2: In-Process Monitoring During the Manufacturing Process

A great final product requires a flawless manufacturing process. We employ real-time monitoring at every critical stage.

Automated Control of Pressing and Curing

Our factory utilizes automated systems to control the vibrocompression and curing processes. We precisely manage pressure, temperature, and time. This ensures every slab achieves optimal density and hardness.

Real-Time Monitoring of Slab Density

Throughout the pressing stage, we monitor slab density in real-time. This prevents inconsistencies and ensures a uniformly solid and non-porous product. It is a key part of what makes us a reliable supplier.

Checks During Polishing and Finishing

During the polishing and finishing stages, our team conducts checks. They ensure the machinery is calibrated correctly. This guarantees a consistent gloss level and smooth surface on every stone product.

Stage 3: Comprehensive Final Product Inspection

What are stone manufacturing standards? At Kangsheng, our final quality inspection is the most rigorous phase. No product earns our name until it passes every test.

Dimensional Accuracy and Thickness Calibration

We use digital calipers and sensors to check all dimensions. Every slab must meet our strict tolerances for length, width, and thickness. This guarantees easy and precise installation for our clients.

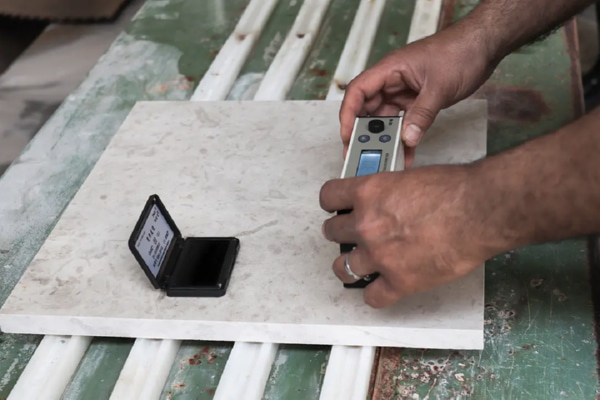

Surface Flatness and Gloss Level Measurement

Our technicians use specialized tools to measure surface flatness and gloss levels. This ensures there are no low spots or inconsistencies in the finish. The result is a perfectly smooth and reflective surface.

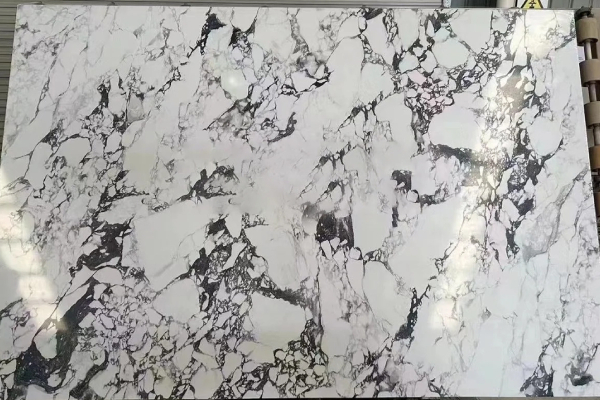

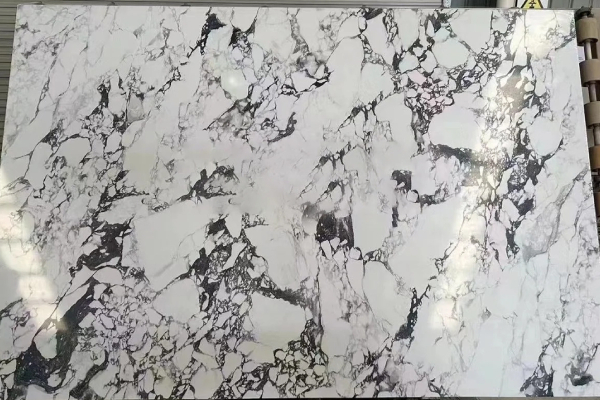

Color and Pattern Matching Against Master Samples

Each finished slab is compared against the approved master sample. This visual inspection ensures that the color, veining, and overall aesthetic match the client's expectations perfectly.

Inspection for Surface Defects

Finally, every square inch of the slab is inspected under bright light for any surface defects. This includes pinholes, blemishes, or scratches. Only flawless slabs pass this final stage of our stone quality control.

Stage 4: Secure, Export-Grade Packaging and Loading Supervision

Our commitment to quality extends beyond the factory floor. We ensure your product arrives safely, no matter the destination.

Sturdy, Custom Wooden Crating

We use strong, heat-treated wooden crates for packaging. These are custom-built to securely hold the slabs and prevent movement during transit.

Protective Film and Corner Guards

Each slab is covered with a protective film to prevent surface scratches. We also add corner guards to protect the most vulnerable parts of the stone.

Supervised Container Loading to Prevent Damage

Our team supervises the loading of every container. We ensure crates are loaded correctly and secured properly. This minimizes the risk of damage during shipping. We take pride in being a dependable global stone supplier.

The Kangsheng Promise: Why Our Quality Control Matters to You

Our meticulous stone quality control process is our promise of excellence.

Reducing Project Risks and Delays

By receiving consistently high-quality products, you reduce the risk of on-site issues. There are no surprise defects or color mismatches. This helps keep your project on schedule and on budget.

Ensuring Long-Term Performance and Durability

Our rigorous standards ensure that every product is built to last. This means a better long-term investment for your clients and a stronger reputation for you.

Building a Foundation for a Long-Term Partnership

We believe that trust is the foundation of any successful partnership. By being transparent about our quality process, we aim to build your confidence. We want to be the trustworthy supplier you can rely on for years to come.

Partnering with Confidence: Our Quality is Your Guarantee

Choosing a stone supplier is a major decision. At Kangsheng Stone, our comprehensive stone quality control system is our guarantee to you. It is our commitment to providing not just a product, but a promise of quality, consistency, and reliability. When you partner with us, you partner with confidence.

Trust is built on transparency. Contact us to learn more about our quality standards or to request a sample quality inspection report for your reference.

Frequently Asked Questions about Our Stone Quality Control

Do you follow any international quality standards?

Yes, our manufacturing process and quality control systems are aligned with international industry standards. We are committed to delivering products that meet global expectations for quality and safety.

Can we arrange a third-party inspection at your factory?

Absolutely. We welcome and encourage third-party inspection. Transparency is a key part of our process, and we are confident in the quality of our products. This is part of what makes us a trustworthy supplier.

How do you handle a product that doesn't meet quality standards?

Any product that does not meet our strict quality standards at any stage is immediately rejected and removed from the production line. It will not be shipped to a client. Our goal is a zero-defect rate on all delivered orders.

What is your standard for color variation between batches?

We strive for the highest level of consistency. By maintaining master samples and precise control over raw materials and pigments, we keep color variation between batches to an absolute minimum, ensuring it is well within accepted industry norms. You can discuss your project's specific needs with our team.

Our Stone Quality Control: A Commitment to Excellence

Our Stone Quality Control: A Commitment to Excellence

Decoding Stone Finishes: Polished vs. Honed vs. Matte

Decoding Stone Finishes: Polished vs. Honed vs. Matte

Beyond the Countertop: Innovative Stone Slab Uses

Beyond the Countertop: Innovative Stone Slab Uses

Optimize Your Project with Cut-to-Size Stone Slabs

Optimize Your Project with Cut-to-Size Stone Slabs

Inside Kangsheng: Our Advanced Stone Fabrication Process

Inside Kangsheng: Our Advanced Stone Fabrication Process

What is Nano Crystallized Glass Stone? A Deep Dive

What is Nano Crystallized Glass Stone? A Deep Dive

Get the Marble Look Without the Maintenance

Get the Marble Look Without the Maintenance

Quartz vs. Granite: A Comparison for Developers

Quartz vs. Granite: A Comparison for Developers

The Ultimate Guide to Engineered Quartz Countertops

The Ultimate Guide to Engineered Quartz Countertops