Optimize Your Project with Cut-to-Size Stone Slabs

In large-scale construction, success is measured by time and money. How does custom fabrication save money? The answer is through strategic project optimization. Moving beyond simply purchasing a slab, our cut to size stone service is designed to save you time, reduce your budget, and improve quality. It is a smarter approach to custom stone fabrication. Learn more about our fabrication services.

The Hidden Costs of On-Site Fabrication

Traditional on-site fabrication seems straightforward but often hides significant costs. Understanding these challenges highlights the value of prefabricated stone.

The Problem of Material Waste

When full slabs are cut on-site, a significant portion often becomes construction waste. Poor layouts and mistakes can lead to unusable offcuts. This waste directly translates to a higher material cost for your project.

Increased Labor and Time On-Site

On-site cutting requires skilled labor and specialized equipment. It is a time-consuming process that can delay other trades. The dust, noise, and space required can disrupt the entire job site, lowering overall efficiency.

Challenges with Quality Consistency

Achieving consistent quality with manual, on-site tools is difficult. Edge profiles can be uneven, and cuts may lack precision. This can lead to a less-than-perfect final installation, impacting the project's overall quality.

Benefit 1: Significant Cost Reduction through Material Optimization

What are the benefits of cut-to-size countertops? The first and most compelling is cost reduction. Our factory-based approach is designed to maximize value.

How Factory Nesting Reduces Waste

We use advanced software to "nest" all your required pieces onto large slabs. This process calculates the most efficient layout. It dramatically reduces material waste compared to on-site cutting. This optimization is a key part of our service.

Lowering Your Overall Material Budget

By minimizing waste, you purchase less raw material. This directly lowers your project's budget. The savings on large, multi-unit projects can be substantial. This makes our service particularly attractive to developers.

A Key Advantage for Stone Wholesale Buyers

For stone wholesale buyers, this efficiency means better margins. You receive pieces that are ready for installation. This reduces your own processing and waste-handling costs. It makes for a more profitable and streamlined operation.

Benefit 2: Accelerate Your Timeline with Ready-to-Install Pieces

How to speed up countertop installation? The answer is to have pieces arrive ready to go. This is a core benefit of our custom stone fabrication service.

Eliminating On-Site Cutting and Dust

With cut to size stone, all cutting is done in our controlled factory environment. This eliminates dust, noise, and disruption on your job site. It creates a cleaner, safer, and more efficient work environment.

Streamlining the Installation Process

Your installation team receives pieces that are precisely cut, with finished edges. They can focus purely on installation. This streamlined workflow for countertop installation significantly shortens the project timeline.

Meeting Tight Project Deadlines

For projects with tight deadlines, every day counts. By removing the on-site fabrication step, you can accelerate your schedule. This helps you meet deadlines and avoid costly penalties. This is a crucial element of effective project management.

Benefit 3: Superior Quality and Precision with Factory-Controlled Fabrication

Is prefabricated stone cheaper? It can be, but its true value also lies in superior quality. Our factory-controlled environment ensures a level of precision that is difficult to match on-site.

The Precision of CNC Machinery vs. Manual Cutting

Our CNC machines execute cuts with digital precision. This ensures every angle is perfect and every curve is smooth. This level of accuracy is far superior to manual cutting methods.

Consistent Edge Profiling and Polishing

All edge profiling and polishing are done on automated machinery. This guarantees a uniform, high-quality finish on every single piece. This consistency elevates the final look of the entire project.

Ensuring a Perfect Fit and Finish

Because every piece is fabricated to exact specifications, the final fit is perfect. This results in tighter seams and a more professional finish. You can be confident in the quality of every countertop and slab. To ensure this quality, we employ a rigorous process.

Ideal Applications for Cut-to-Size Stone Services

This service is a powerful tool for a variety of large-scale projects.

Multi-Unit Residential Projects (Kitchens & Baths)

For apartment buildings or housing developments, standardizing kitchen and bathroom countertops with our service is ideal. It ensures consistency and speeds up the finishing of hundreds of units.

Hospitality (Hotel Vanities & Bar Tops)

Hotels require durable and consistent surfaces for vanities, desks, and bar tops. Our cut to size stone service delivers the quality and efficiency needed for the hospitality industry.

Commercial Wall Cladding and Flooring

For large commercial spaces, we can provide pre-cut wall panels and flooring tiles. This simplifies the installation of complex patterns and large surface areas.

A Smarter Way to Build: The Strategic Value of Cut-to-Size Stone

In modern construction, project optimization is key. Our cut to size stone service is more than just a product; it's a strategic solution. By leveraging our custom stone fabrication capabilities, you can reduce costs, shorten timelines, and improve quality. It is a smarter, more efficient way to manage your stone supply chain and achieve superior results.

Ready to optimize your next project? Submit your project specifications to our team today and receive a custom quote for our cut-to-size services.

Frequently Asked Questions about Our Custom Fabrication Services

What is the minimum order quantity for cut-to-size services?

We primarily cater to stone wholesale and project-based orders. The minimum order quantity depends on the project's scope. Please contact our team with your project details for more information.

What information do I need to provide to get a quote?

To provide an accurate quote, we need detailed drawings or a cutting list with dimensions, edge profiles, and quantities for each piece. The more information you provide, the more precise our quote will be.

How does the lead time for cut-to-size compare to ordering full slabs?

The lead time for prefabricated stone can be slightly longer due to the fabrication process. However, this is often offset by the significant time savings during on-site installation.

How are the cut-to-size pieces packaged for shipping?

Each ready-to-install piece is carefully labeled and packaged in our export-grade wooden crates. We design the packaging to protect all finished edges and surfaces during international transport.

Optimize Your Project with Cut-to-Size Stone Slabs

Optimize Your Project with Cut-to-Size Stone Slabs

Inside Kangsheng: Our Advanced Stone Fabrication Process

Inside Kangsheng: Our Advanced Stone Fabrication Process

What is Nano Crystallized Glass Stone? A Deep Dive

What is Nano Crystallized Glass Stone? A Deep Dive

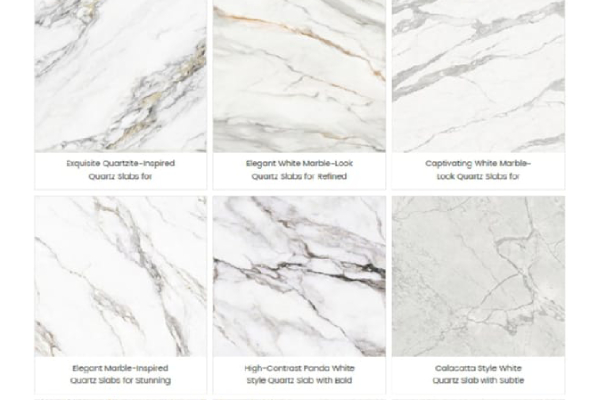

Get the Marble Look Without the Maintenance

Get the Marble Look Without the Maintenance

The Ultimate Guide to Engineered Quartz Countertops

The Ultimate Guide to Engineered Quartz Countertops

Quartz vs. Granite: A Comparison for Developers

Quartz vs. Granite: A Comparison for Developers