Understanding Wholesale Stone Price: Key Cost Factors

For any stone distributor or developer, understanding the true wholesale stone price is essential for project success. How is stone cost calculated? It's more than just a single number. The final price is influenced by several critical cost factors. This guide will decode stone bulk pricing. We'll help you maximize value for your next project. For a transparent pricing model, explore what Kangsheng Stone offers.

Factor 1: Raw Material Grade and Complexity

What factors influence stone prices? The journey of a stone slab begins with its raw materials, which are a primary driver of cost.

The Cost of High-Purity Quartz Crystals

The quality and purity of the natural quartz crystals used in a quartz slab directly impact its performance and cost. Higher-purity quartz results in a stronger, clearer, and more durable final product. This premium raw material naturally carries a higher price.

Pigment and Resin Quality

The quality of pigments and resins also plays a significant role. High-performance resins ensure better durability and color stability. Superior pigments create richer, more consistent colors. Investing in quality components affects the overall quartz slab cost.

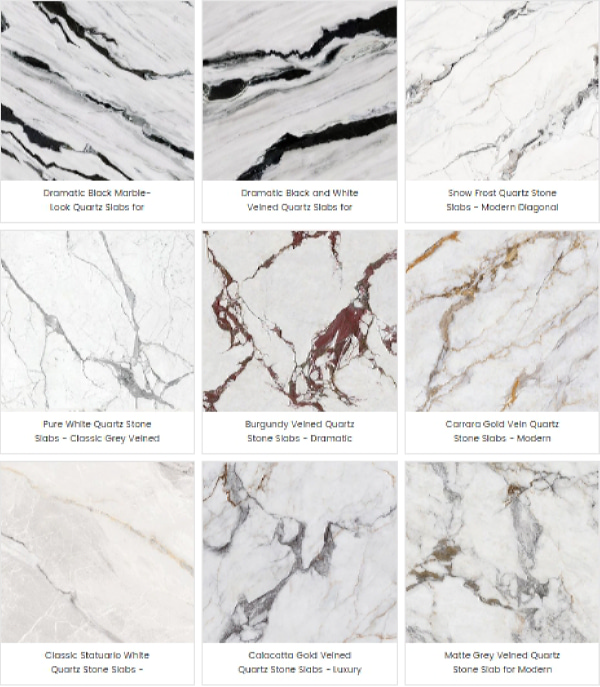

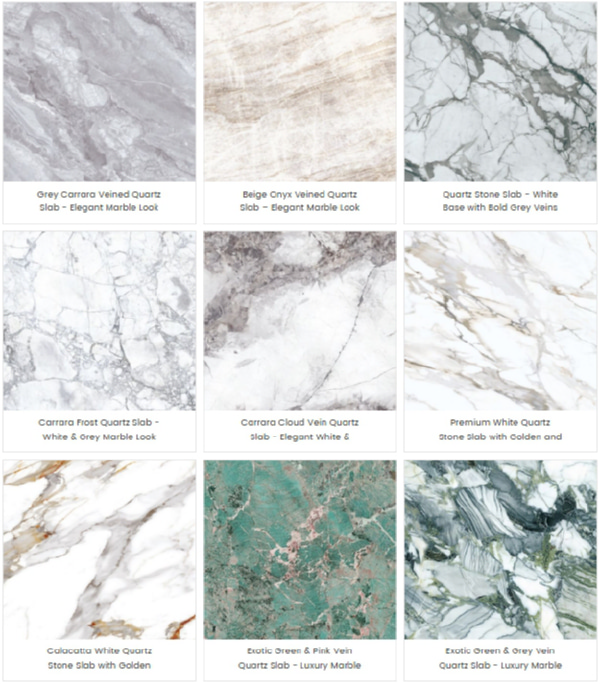

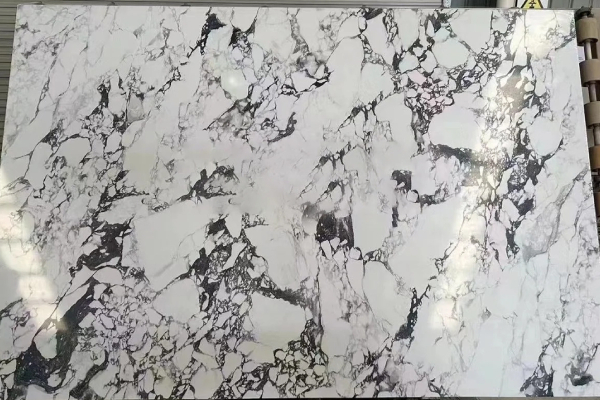

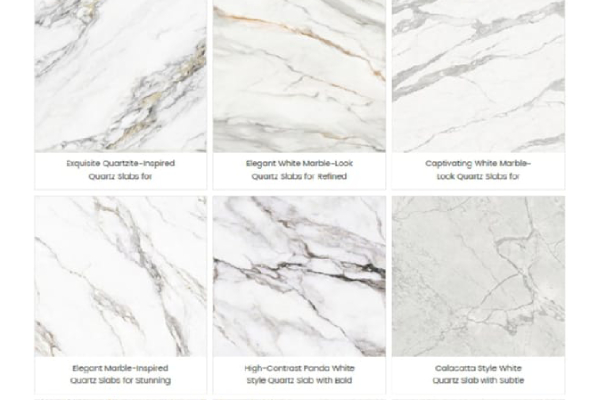

Pricing for Simple vs. Complex Veining

A simple, solid-color slab has a different cost profile than one with intricate, multi-layered veining. Designs that mimic rare marbles require more complex production techniques and materials. This added complexity is reflected in the final pricing.

Factor 2: Slab Thickness and Size

The physical dimensions of the slab are a straightforward but important cost factor. More material means a higher price.

Comparing 2cm vs. 3cm Slab Costs

A 3cm thick slab contains 50% more material than a 2cm slab. This directly increases the raw material cost and weight. While 3cm slabs offer a more substantial look, it's important to factor this into your budget.

Standard Slabs vs. Jumbo Slabs

Jumbo slabs offer the advantage of fewer seams in large installations. However, producing these larger slabs requires specialized equipment. This often results in a higher per-square-foot stone slab price compared to standard sizes.

How Size Impacts Material Yield

The size of the slab you choose can impact your project's material yield. Sometimes, a jumbo slab can lead to less waste on a large kitchen island. This can partially offset its higher initial cost.

Factor 3: The Impact of Surface Finish

The finish of the stone surface also influences the final wholesale stone price.

Standard Polished Finish Pricing

A polished finish is typically the standard and most cost-effective option. The machinery and process for polishing are highly optimized.

The Cost of Honed and Matte Finishes

Honed and matte finishes often require additional processing steps. Creating a uniform, non-reflective surface can be more complex. This can add a premium to the quartz slab cost.

Special Textures and Their Price Implications

Some manufacturers offer special textures, like a leathered or brushed finish. These unique surfaces require specialized techniques and will typically be priced higher than standard finishes.

Factor 4: Order Volume and Stone Bulk Pricing

Is bulk stone pricing cheaper? Yes, for any stone distributor, order volume is the most powerful tool for price negotiation.

The Principle of Economies of Scale

Manufacturers achieve greater efficiency when producing large quantities of the same product. We pass these savings on to our clients. This is the core principle of stone bulk pricing.

Tiered Pricing for Different Quantities

We often offer tiered pricing. A single-container order will have a better price than a less-than-container load (LCL) order. Multi-container orders can achieve even greater discounts.

Benefits for Container-Load Orders

Ordering a full container load is the most cost-effective way to wholesale stone. It optimizes shipping costs and unlocks the best possible price per slab. Ask us about our container pricing.

Factor 5: Custom Fabrication and Complexity

How to get a good price on quartz slabs? It's important to understand how customization affects the cost.

Pricing for Cut-to-Size Services

Our cut-to-size service adds value by saving you time and on-site labor. The price for this service is based on the complexity and number of cuts. However, it often reduces overall project costs.

The Cost of Edge Profiling

A simple eased edge will be more affordable than a complex, multi-layered ogee edge. The amount of labor and machine time required for custom fabrication will be factored into the final quote.

Additional Charges for Sink or Cooktop Cutouts

Precise cutouts for sinks, faucets, and cooktops require specialized CNC machinery. These services will have an additional charge based on the number and complexity of the cutouts.

How to Optimize Your Quartz Slab Cost Without Sacrificing Quality

Understanding the cost factors empowers you to make smarter purchasing decisions.

Plan Your Layout to Maximize Slab Yield

Work with your fabricator to plan the layout of your countertop pieces on the slab. Efficient planning can significantly reduce waste and lower the number of slabs you need to purchase.

Choose the Most Cost-Effective Thickness for Your Application

For most residential applications, a 2cm slab is perfectly durable and more affordable. A 3cm slab is often preferred for a more substantial look or for large, unsupported overhangs.

Consolidate Orders to Achieve Better Bulk Pricing

If possible, consolidate your orders to meet the thresholds for better stone bulk pricing. Planning your inventory needs for several months can lead to significant savings.

Beyond the Price Tag: Partnering with a Transparent Stone Distributor

Understanding the wholesale stone price is about seeing beyond the final number. It is about recognizing the value in the raw materials, manufacturing process, and services provided. A transparent stone distributor like Kangsheng Stone will work with you to find the best balance of quality, performance, and cost for your project.

Ready for a clear and competitive quote? Contact our team with your project details to receive a transparent, no-obligation wholesale stone price breakdown.

Frequently Asked Questions about Stone Bulk Pricing

What is included in a wholesale stone price?

Typically, a wholesale stone price from us includes the cost of the slab itself and standard export packaging. Services like custom fabrication and shipping are usually quoted separately so you can see a clear breakdown of costs.

How do you provide a quote for a mixed container of different products?

We can easily provide a quote for a mixed container. The pricing for each type of slab will be calculated based on its specific characteristics and the quantity of each. This allows our clients to have great flexibility in their orders.

Are there any hidden costs I should be aware of?

As a transparent stone distributor, our goal is to eliminate hidden costs. Our quotes are detailed and comprehensive. We will always clarify what is included, such as port fees or documentation charges.

How long is a wholesale price quote valid for?

Due to fluctuations in raw material costs, our price quotes are typically valid for a specific period, often 30 days. We always state the validity period clearly on our quotations. For the most current pricing, it's always best to get in touch with our sales team.

Understanding Wholesale Stone Price: Key Cost Factors

Understanding Wholesale Stone Price: Key Cost Factors

How to Evaluate a Stone Supplier: 7 Key Questions

How to Evaluate a Stone Supplier: 7 Key Questions

Checklist for Importing Stone Slabs from China

Checklist for Importing Stone Slabs from China

Our Stone Quality Control: A Commitment to Excellence

Our Stone Quality Control: A Commitment to Excellence

Decoding Stone Finishes: Polished vs. Honed vs. Matte

Decoding Stone Finishes: Polished vs. Honed vs. Matte

Beyond the Countertop: Innovative Stone Slab Uses

Beyond the Countertop: Innovative Stone Slab Uses

Optimize Your Project with Cut-to-Size Stone Slabs

Optimize Your Project with Cut-to-Size Stone Slabs

Inside Kangsheng: Our Advanced Stone Fabrication Process

Inside Kangsheng: Our Advanced Stone Fabrication Process

What is Nano Crystallized Glass Stone? A Deep Dive

What is Nano Crystallized Glass Stone? A Deep Dive

Get the Marble Look Without the Maintenance

Get the Marble Look Without the Maintenance